Table of Content

They were very friendly and accommodating to give me plenty of time to have them inspect with enough time respond to the sellers of the property if there was an issue. The other services I called would have inspected 1-2 days before the end of the option period and were not friendly at all. The technician was running behind and kept in great communication so my realtor and I weren't just standing around wondering. I recommend David of Texan Inspection Services without reservation.

Avoid costly unscheduled shutdowns, maximize the efforts of your maintenance personnel, and increase your workplace safety by scheduling a routine infrared inspection today. I have used Texan Inspections several times and these guys are very knowledgeable about housing construction and utility systems. Very complete and easy to read reports issued quickly after the inspection. Inspector was willing to spend all the time needed to go over the results and advice on path forward for the finding.

Comparative thermography

There was a time when building inspections were inefficient and also erroneous at times. But, with infrared technology and abled thermographers readily available, it doesn’t need to be so anymore. No matter whether it’s a century-old house or a month-old home, a detailed inspection report is a prerequisite. That’s because it lets you know the overall condition of the property you are interested in buying. Previous blog, infrared inspections can save you up to $11,000 in building repairs. That’s because it detects problems much before they get bigger and become a headache for you.

Moisture meters, AFCI/GFCI testers, CO analyzers, PPE, and many more have all helped shorten the amount of time it takes for an inspector to complete a job. Some of these tools made the job safer, some made it faster, and some allowed inspectors to add new services with their reports. Thermography and infrared technology fits all of these categories and has become a leading service that all inspectors should be trained in. Active infestations of termites, rodents, and other pests produce visible heat that can be picked up by thermal imaging.

What Will an Infrared Thermography Inspection Reveal?

Energy auditors may use thermography -- or infrared scanning -- to detect thermal defects andair leakagein building envelopes. The use of thermal imaging or thermography can be applied to just about any situation where taking these temperature reading will provide useful data. We use thermography for preventative maintenance, troubleshooting specific quantitative issues, condition assessment, research and development, medical and veterinary science. In other words, with what I know and having seen from what I’ve inspected in over 15,000 inspections, using thermal imaging or an infrared camera to perform inspections during a home inspection is a must. With infrared camera’s color gradient display, inspectors identify hot spots to pinpoint affected components.

We all know that prevention is better than a cure, making infrared thermographic scans the ideal cost-effective way to check for faults before they become a bigger problem. Thermographic inspections evaluate the temperature profiles of a residential or commercial building to diagnose for predictive maintenance. Instead, infrared technology helps us take color images of the surveying/inters area. For example, a qualified thermographer often conducts quantitative checks, which measure exact temperature and/or temperature distribution.

How Can It Provide a More Thorough Inspection?

Brent was our home inspector, he was very knowledgeable and took time to answer some of the question we had as we are first time house buyers. Kathleen from the office, whom i set up appointments with was very friendly and professional as well. I had to change my appointment couple of time due the construction not being done on time and Kathleen was very considerate of my situation. I will recommend anyone looking for home inspection to go with this company. I will be contacting them again for 11th Month Warranty Inspection as well.

Commercial building inspections, infrared thermography can cover a huge area in little time. In addition to using thermography during an energy assessment, you should have a scan done before purchasing a house; even new houses can have defects in their thermal envelopes. You may wish to include a clause in the contract requiring a thermographic scan of the house. A thermographic scan performed by a certified technician is usually accurate enough to use as documentation in court proceedings. Thermographic scans are also commonly used with ablower door testrunning.

Can Our Infrared Thermal Imaging & Scanning Team Help You?

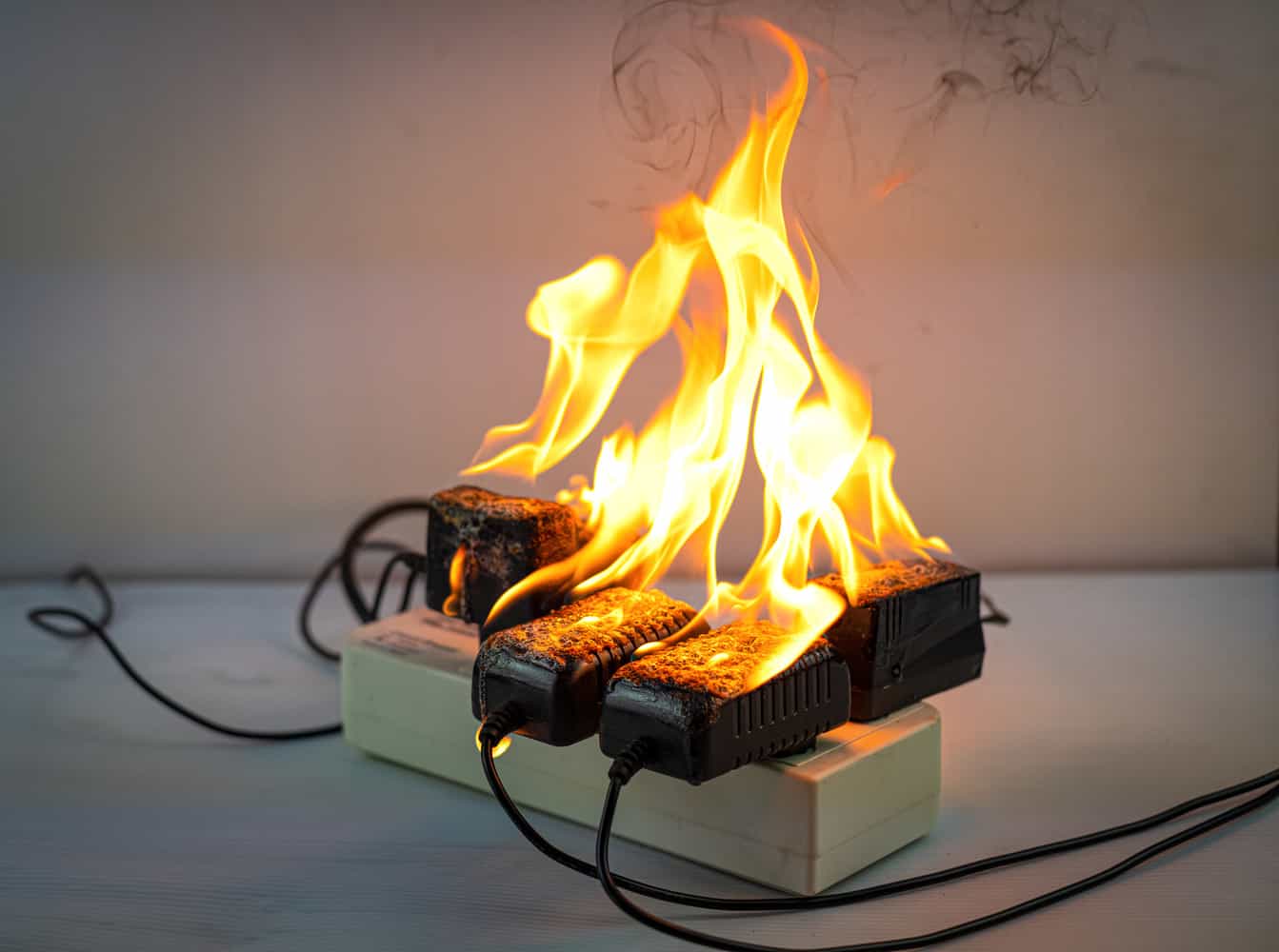

So let’s get down to business without further ado and begin with a basic overview of IR thermography. You see, leaving these problems unaddressed will only cost you big in the future in terms of large-scale repair and restoration. Also, it can reveal moisture hidden within your home’s structure, which can be the source of roof leaks, mold, etc. For a limited time, we’re offering 10% off any of our add-on services using code online10 when you schedule your next appointment HERE. Electrical issues such as loose connections in electrical panels, switches, and outlets as well as other electrical problems that can cause overheating and fire.

The process of “viewing” and “measuring” invisible infrared radiation emitted from an object is known as infrared thermography. It involves the use of an infrared imaging and measurement camera. The oil and gas sector extensively uses infrared thermography as an inspection tool for condition monitoring and predictive maintenance. Milestone structural inspection is simply incomplete without an infrared thermographer since many structural components need infrared analysis.

It can useful to identify hot spots in essential process equipment that professionals can fix and restore beforehand to prevent a catastrophic failure of the machinery or production process. In the manufacturing of automotive components, when even the smallest flaw is intolerable, it is tremendously beneficial. An online system uses a thermal imager to gauge the temperature of the distribution products’ surface. The following are some essential applications of infrared thermography you must understand.

Areas that are dry have less thermal mass and will change temperature quickly. On the other hand, areas with a higher thermal mass, which may include damp areas, will change temperature more slowly. These differences will be obvious when viewed through the infrared camera. Then, depending on the findings, the inspector will explain what anomalies were found and provide recommendations to repair them. When I first received my infrared camera back in the early 2000’s, my eyes were opened to all the issues I was missing. From water inside walls and ceilings to electrical issues in panels and within the home or business itself.

You should develop severity criteria before employing infrared thermography as a condition monitoring method. IR thermography is known as thermal imaging, infrared thermometry, thermal testing, or infrared thermography testing. So we cannot overstate the importance of infrared thermography inspections for safe housing.

No comments:

Post a Comment